Anodizing is an electrochemical process that provides a durable and corrosion-resistant anodic oxide finish to a metal surface. Although other nonferrous metals, such as magnesium and titanium, can also be anodized, aluminum is best suited for the process. The aluminum substrate serves as the source of the anodic oxide structure, which is composed entirely of aluminum oxide. Read More…

Alexandria Metal Finishers provides many finishing services, one of which is anodizing. Hardcoat anodizing, aluminum anodizing, hardcoat with Teflon® plus chromic and sulfuric anodizing are some of our processes. We provide services to aerospace, commercial, electronics, medical industries and more.

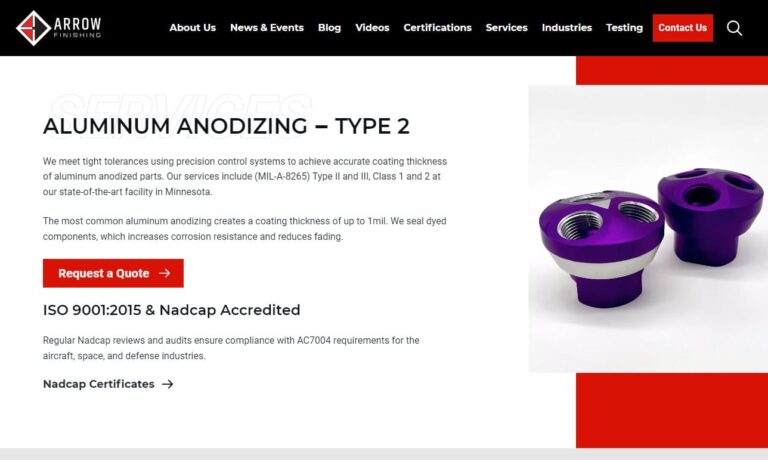

We specialize in aluminum anodizing, chromate conversion coatings, hard anodizing and sulfuric anodizing. To assure process repeatability and finish consistency, we use computer-controlled processing. All of our processes meet military specifications. Our quality system is certified to ISO 9001:2015, AS-9100 Rev D & NADCAP.

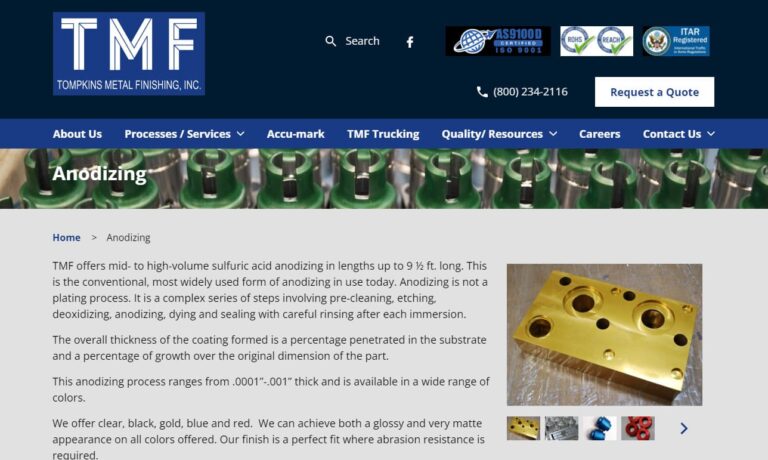

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

At Alexandria Metal Finishers, Inc., we are proud to offer comprehensive aluminum anodizing services tailored to the specific needs of our customers. We deliver high-quality anodized aluminum products that meet the highest standards of durability, aesthetics, and performance. Our aluminum anodizing process involves carefully preparing the surface of aluminum components and subjecting them to an...

When you choose INCERTEC, you're choosing a partner committed to excellence in every aspect of aluminum anodizing. Trust us to meet your specific requirements with a dedication to quality that goes beyond expectations. Reach out to us today for more information, and let us elevate your projects to new heights.

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Anodizing Manufacturers

Rather than being applied to the surface like paint or plating, this aluminum oxide is integrated within the underlying metal substrate itself, making it resistant to chipping and peeling. Anodized aluminum’s well-organized porous structure enables further procedures like coloring and sealing.

The Anodizing Process

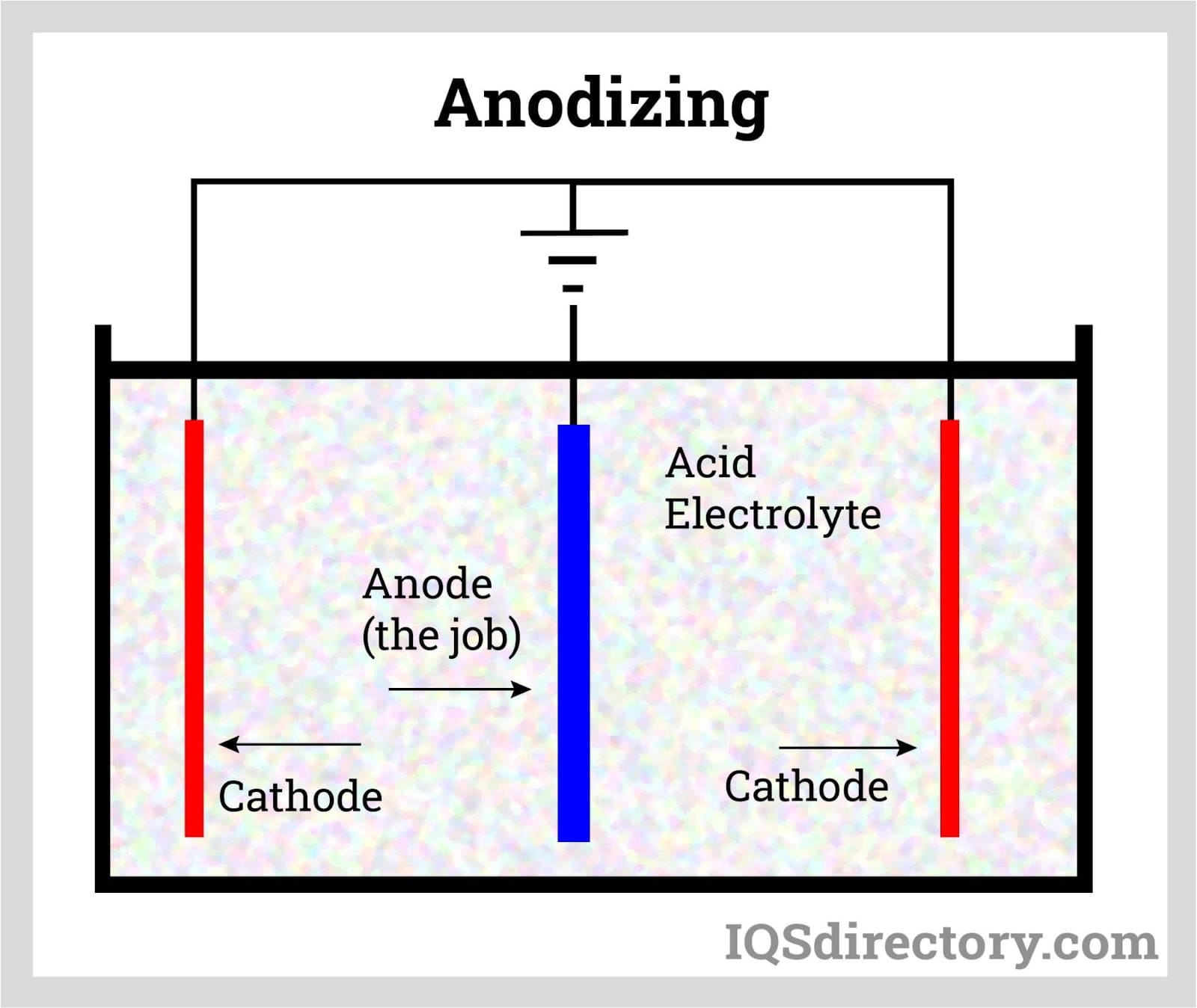

Aluminum is anodized by dipping it into an acid electrolyte tank and then running an electric current through it. The anodizing tank has a cathode mounted inside of it; aluminum serves as the anode, causing oxygen ions to be released from the electrolyte and become combined with atoms on the surface of the component (in this case, aluminum) being anodized. Therefore, anodizing is the amplification of a naturally-occurring phenomenon by carefully regulated oxidation.

The Various Anodizing Processes

- Surface Coating

- Integral Coloring

- Organic Dyeing

- Inorganic Dyeing

- Electrolytic Coloring

Surface Coating

The process of enhancing the naturally-occurring oxide layer that forms on the surface of aluminum when it comes into contact with oxygen is known as electrochemical surface treatment (surface coating), or anodizing. Through this process, the electrical current increases the oxide layer, making the surface of the aluminum more durable.

Working Method:

Integral Coloring

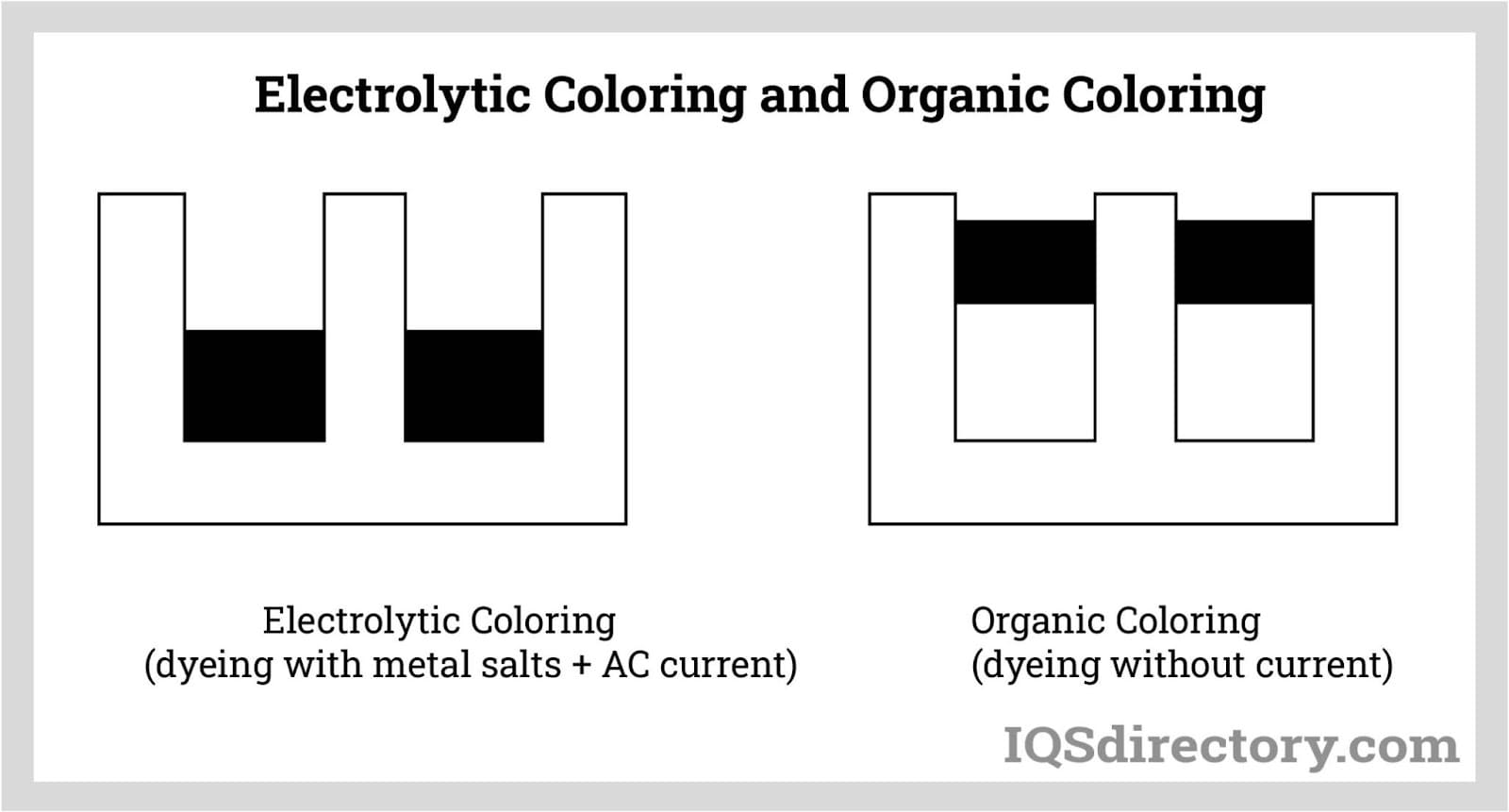

Integral color just means that both coloring and anodizing happen in one process. In two-step anodizing, the aluminum is electrolytically coated with tin salts after being anodized in sulfuric acid first. Using the integral coloring process, the metallic character of the aluminum is retained.

Organic Dyeing

The metallic quality of aluminum is preserved by organic dyes and they help create a high degree of brilliance in the aluminum. The actual coloring of the aluminum oxide coating is a pretty easy operation. The dyebath is composed of a water solution containing between 0.025 and 1.090 dyestuff at a temperature of 150°F. The previously anodized aluminum is merely submerged for a brief period of time in this bath, typically 10 minutes.

Inorganic Dyeing

With inorganic dyeing, the anodic film is a little duller than with organic dyeing, especially in gold tones, yet the metallic quality is retained.

Electrolytic Coloring

Whenanodized aluminum, the cathode is either metal or graphite, while the anode is the aluminum workpiece. Depending on the salt solution and the AC voltage used during electrolysis, the oxide or hydroxide that precipitates within the pores gives the film colors like brown, bronze, blue, yellowish gray, or black. Aluminum's metallic nature, however, is kept.

The Environmental Benefits of Anodizing Aluminum

- The benefits of aluminum for the environment should be well known. As one of the strongest, yet lightweight, metals, aluminum promotes better fuel efficiency in the planes, boats, and automobiles where it is utilized.

- Unlike other materials, aluminum is already readily recycled. Approximately one-third of all aluminum produced in the United States today comes from recycled materials, according to the Aluminum Association, saving nearly 95% of the energy needed to make aluminum from raw materials.

- In terms of its effects on the environment, anodized aluminum is a "naturally green" substance. Aluminum's material advantages are enhanced by anodizing and this procedure is reasonably benign when compared to the processing of other materials and technologies.

- After undergoing the anodizing process, the resulting aluminum product is tougher and has a longer lifespan so that it will not need to be replaced as regularly of similar products made from other materials.

- Additionally, the anodizing process promotes lubricity and decreases friction, which is advantageous for the various parts and components that are made from anodized aluminum. These qualities promote increased wear resistance and longer life cycles for the machines and equipment in which they are utilized which, ultimately, leads to less waste or less energy consumption required to recycle materials.

Benefits of Anodizing Aluminum

- Durability: The anodizing process prolongs the life and toughness of aluminum. The majority of anodized products have extraordinarily long lifespans and provide significant financial benefits due to the maintenance and operating cost savings associated with its durability. Items made of anodized aluminum last longer and require replacement or maintenance less often.

- Stability of color: Exterior anodic coatings are easy to match and repeat, offer good stability to ultraviolet light, and don't chip or peel.

- Maintenance is simple: There are hardly any scars or wear from fabrication, handling, installation, routine surface dirt cleaning, or use. An anodized surface may typically be cleaned with mild soap and water or rinsed to bring back its original appearance. For harder deposits, mild abrasive cleansers can be used.

- Aesthetics: Anodizing decreases or completely removes color inconsistencies while providing a vast array of gloss and color options. Anodizing, as opposed to other finishes, enables aluminum to keep its metallic appearance.

- Cost: Greater long-term value is produced through lower original finishing costs combined with lower maintenance expenditures.

- Safety and health: Anodizing is a harmless technique that has no negative effects on health. Anodized finishes are non-toxic, chemically stable, won't break down, and can withstand heat up to the melting point of aluminum (1,221° F).

- The anodizing process is non-hazardous and creates no toxic or dangerous byproducts because it is a naturally-existing oxide reaction.

Choosing the Proper Anodizing Company

To make sure you have the most constructive outcome when purchasing Anodizing from an Anodizing Company, it is important to compare at least 4 or 5 Companies using our Anodizing directory. Each Anodizing Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Anodizing business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Anodizing businesses with the same message.

Aluminum Anodizing

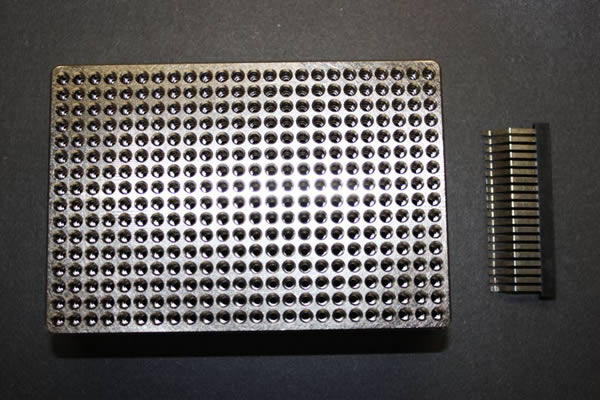

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services