A wide variety of products can be subject to bright dip anodizing, including products such as camera and mp3 player cases, food and beverage containment, cookware, architectural accent pieces, sports equipment, framing and automotive construction as well as more industrial components such as manufacturing and plant equipment. Read More…

Alexandria Metal Finishers provides many finishing services, one of which is anodizing. Hardcoat anodizing, aluminum anodizing, hardcoat with Teflon® plus chromic and sulfuric anodizing are some of our processes. We provide services to aerospace, commercial, electronics, medical industries and more.

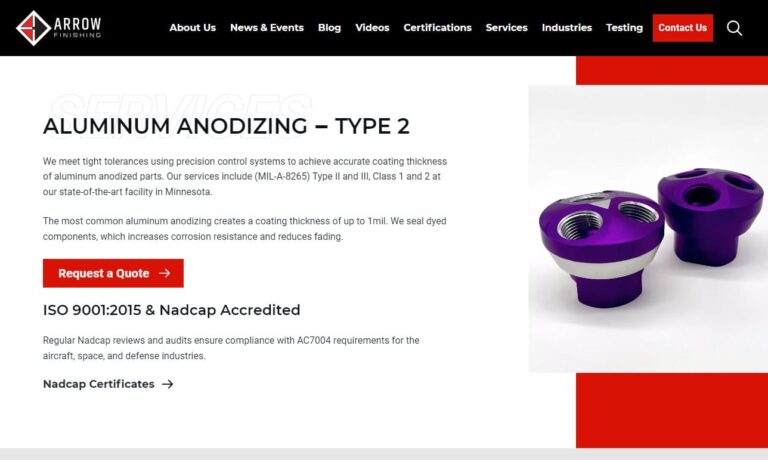

We specialize in aluminum anodizing, chromate conversion coatings, hard anodizing and sulfuric anodizing. To assure process repeatability and finish consistency, we use computer-controlled processing. All of our processes meet military specifications. Our quality system is certified to ISO 9001:2015, AS-9100 Rev D & NADCAP.

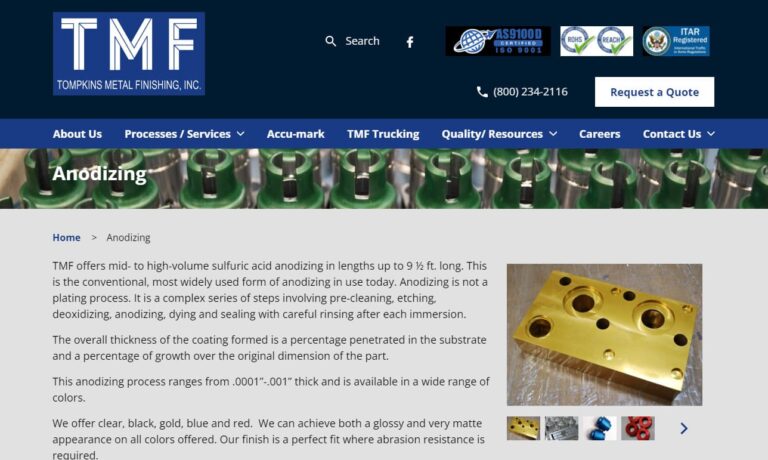

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

At Alexandria Metal Finishers, Inc., we are proud to offer comprehensive aluminum anodizing services tailored to the specific needs of our customers. We deliver high-quality anodized aluminum products that meet the highest standards of durability, aesthetics, and performance. Our aluminum anodizing process involves carefully preparing the surface of aluminum components and subjecting them to an...

When you choose INCERTEC, you're choosing a partner committed to excellence in every aspect of aluminum anodizing. Trust us to meet your specific requirements with a dedication to quality that goes beyond expectations. Reach out to us today for more information, and let us elevate your projects to new heights.

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Bright Dip Anodizing Manufacturers

The popularity of this process as opposed to alternatives such as electro-polishing and coating can be attributed to the unique benefits afforded by the bright dip process. Though the results vary, bright dipped aluminum has a glossy, high luster appearance and may even result in a reflective, mirror-like finish.

This gloss is achieved through bright dipping without leaving deposits on the surface of the part as do many other finishing processes. Depending on the grade of the aluminum, the process is also very fast, taking as little as 30 seconds to complete. The most suitable aluminum alloys for bright dipping are 5357, 5457, 6063, 7016 and 7016.

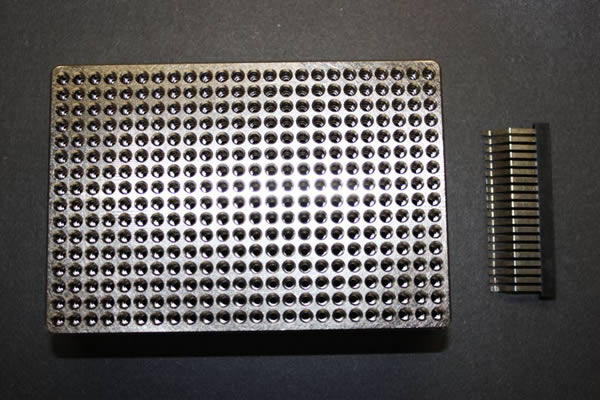

Bright dipping and anodizing are actually completed in two separate steps with bright dipping pertaining to the aesthetic of the metal and anodizing improving hardness and resistance to corrosion and wear. Bright dipping occurs first as a pretreatment to the anodizing process. A relatively simple concept, the aluminum component is dipped into a double walled, stainless steel tank filled with the brightening solution and heated to above 200 deg F.

The solution is a chemical bath that smooths the surface on a microscopic level, resulting in the desired sheen. Though mixes will vary, the basic composition involves phosphoric/nitric acid. Acetic and sulfuric acid are common additives. Due to the use of harsh chemicals and high heat, the bright dipping component of this total process requires careful calculation and is regulated by worker safety and environmental laws. The bath should be carefully racked and agitated in a rocking motion to avoid spotting due to gaseous bubbles on the surface of the part.

Other considerations include proper ventilation and a warm rinse tank. Once the desired shine is achieved, the part must be washed several times prior to anodizing. There are two main ways that metal is anodized: bath anodizing and anodic painting. The more common of the two is bath anodizing, which involves fully immersing the metal in a tub of the anodizing acid.

Once the metal is submerged, a power supply is turned on that introduces an electrical current to the bath. The resulting reaction changes the surface of the metal into a thin film of metal oxide. The total results are increased corrosion and wear resistance as well as cosmetic enhancement.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services