Danco Metal Surfacing

Danco Metal SurfacingRequest A Quote

Arcadia, CADanco Anodizing is a leading provider of high-quality aluminum anodizing services, serving customers in a variety of industries since 1971. Located in Ontario, California, Danco Anodizing has built a reputation for delivering exceptional service and reliable results. Aluminum anodizing is a process that enhances the durability, corrosion resistance, and aesthetic appeal of aluminum parts and products. It involves immersing the aluminum in an electrolytic solution and passing an electric current through it, causing an oxide layer to form on the surface of the aluminum. This oxide layer can then be dyed or sealed to create a variety of colors and finishes. Danco Anodizing offers a wide range of aluminum anodizing services, including Type II anodizing, Type III anodizing, hardcoat anodizing, and chromic acid anodizing. Type II anodizing is the most common type of anodizing and is used to create a decorative, corrosion-resistant finish. Type III anodizing, also known as hardcoat anodizing, produces a thicker, more durable oxide layer and is commonly used in applications where wear resistance is critical. Chromic acid anodizing is a process used for parts that cannot be exposed to the high temperatures of other anodizing processes. Danco Anodizing has extensive experience working with a wide range of aluminum alloys, including 6061, 6063, 2024, 7075, and more. They can anodize parts up to 40 feet in length and have the capacity to handle both small and large production runs. In addition to their anodizing services, Danco Anodizing offers a variety of value-added services, including masking, packaging, and shipping. They also offer custom color matching, allowing customers to create unique finishes that meet their specific needs and requirements. Danco Anodizing is committed to delivering high-quality products and services that meet or exceed customer expectations. They maintain a comprehensive quality management system and are ISO 9001:2015 certified. Their team of skilled professionals is dedicated to providing exceptional service and ensuring that every customer's needs are met. Overall, Danco Anodizing is a trusted and experienced provider of aluminum anodizing services, offering a wide range of capabilities and value-added services. Whether you need a decorative finish for your product or a highly durable coating for an industrial application, Danco Anodizing has the expertise and resources to deliver the results you need.

Aluminum Anodizing

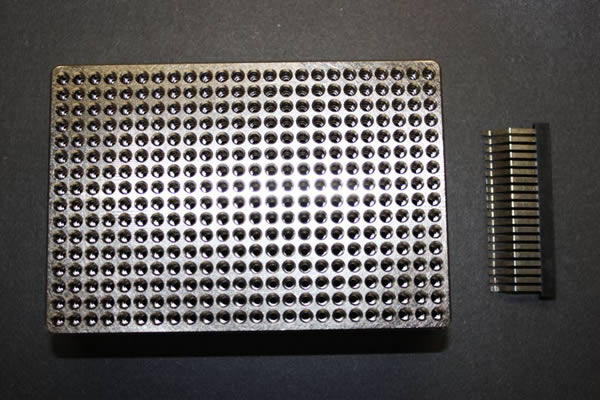

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services