To understand how a metal can be dyed black, the basic process of anodization should be understood. Anodizing involves using a corrosive chemical and electrical current to alter the chemical body of certain metals and make them stronger in the process. Read More…

Alexandria Metal Finishers provides many finishing services, one of which is anodizing. Hardcoat anodizing, aluminum anodizing, hardcoat with Teflon® plus chromic and sulfuric anodizing are some of our processes. We provide services to aerospace, commercial, electronics, medical industries and more.

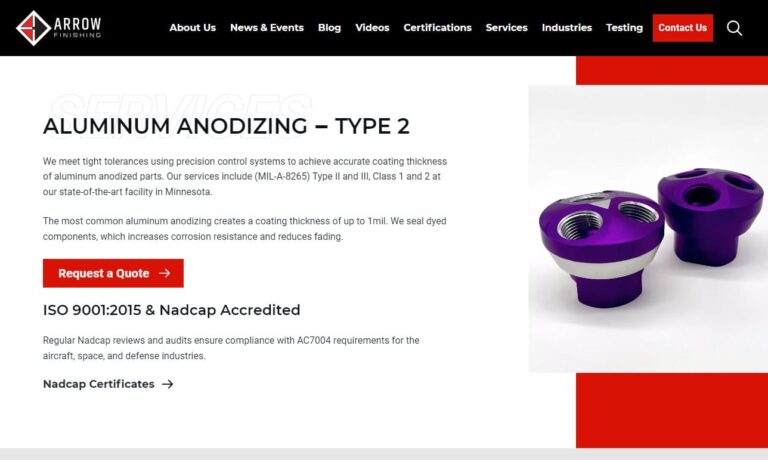

We specialize in aluminum anodizing, chromate conversion coatings, hard anodizing and sulfuric anodizing. To assure process repeatability and finish consistency, we use computer-controlled processing. All of our processes meet military specifications. Our quality system is certified to ISO 9001:2015, AS-9100 Rev D & NADCAP.

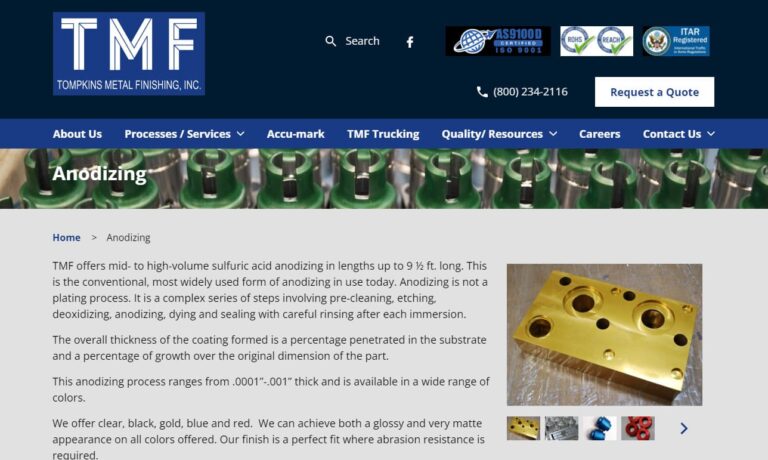

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

At Alexandria Metal Finishers, Inc., we are proud to offer comprehensive aluminum anodizing services tailored to the specific needs of our customers. We deliver high-quality anodized aluminum products that meet the highest standards of durability, aesthetics, and performance. Our aluminum anodizing process involves carefully preparing the surface of aluminum components and subjecting them to an...

When you choose INCERTEC, you're choosing a partner committed to excellence in every aspect of aluminum anodizing. Trust us to meet your specific requirements with a dedication to quality that goes beyond expectations. Reach out to us today for more information, and let us elevate your projects to new heights.

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Black Anodizing Manufacturers

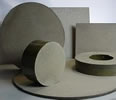

There are many types of anodizing acids, including sulfuric and chromic as the major anodizing contenders. However, some acids such as organic and boric are used in custom anodizing situations because they can offer more control in smaller settings. Metals commonly anodized are aluminum, titanium, magnesium and zinc. The new characteristics of an anodized metal are increased strength and corrosion resistance, a thicker and smoother protector then regular paint or metal plating. However, the process does make the metal more brittle, so extreme temperatures can cause damage. Depending on the style of anodizing and the type of metal, dying the product is possible.

Because the basic black dye is made from an inorganic substance, a chemical mixture called ferric ammonium oxalate, dyes used in black anodizing tend to be more lightfast. The same chemical is used to produce gold dye. To be lightfast means that the colors tend not to fade as quickly. This is true of any inorganic dye used during an anodizing process.

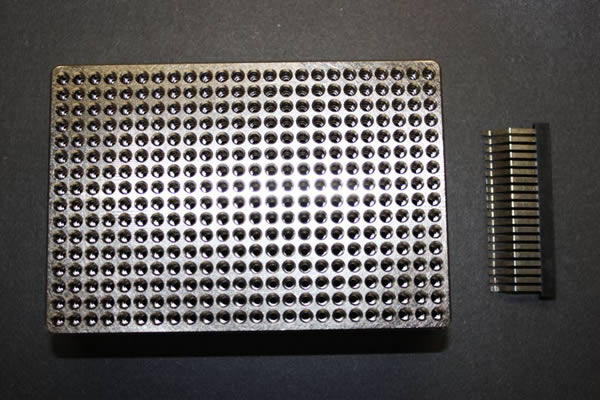

Black anodizing is produced in the same basic fashion that all colors for anodizing are produced, although there are a couple alternative processes too. Most anodizing processes, such as the sulfuric acid, make the surface of a metal more porous and therefore able to soak and retain the color of dyes. So directly after the major chemical shift in the metal's crystal structure, a dye can be applied.

Once a metal has been dyed, hot water or steam, often mixed with nickel acetate, is used to seal the surface and to convert the oxide into its hydrated form. This process decreases the potential of bleeding and can improve corrosion resistance. A black anodized product can also be made by way of metal dyes, which are electrolytically deposited in the pores.

Organic dyes are actually used during the chemical immersion of a product. The dying process is utilized in almost every industry and application non-colored anodized products are. A couple examples include the electronic field, which sells colored Mp3 players, flashlights and cameras, and the cooking industry, which often markets two-toned cookware.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services