Hard anodizing (also known as hardcoat anodizing) is the process of applying a dense anodic coating of aluminum oxide by converting an aluminum alloy component that has been thoroughly cleaned and deoxidized into an oxide film using an appropriate electrolyte to make it thicker and more abrasion-resistant. Read More…

Alexandria Metal Finishers provides many finishing services, one of which is anodizing. Hardcoat anodizing, aluminum anodizing, hardcoat with Teflon® plus chromic and sulfuric anodizing are some of our processes. We provide services to aerospace, commercial, electronics, medical industries and more.

We specialize in aluminum anodizing, chromate conversion coatings, hard anodizing and sulfuric anodizing. To assure process repeatability and finish consistency, we use computer-controlled processing. All of our processes meet military specifications. Our quality system is certified to ISO 9001:2015, AS-9100 Rev D & NADCAP.

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

At Alexandria Metal Finishers, Inc., we are proud to offer comprehensive aluminum anodizing services tailored to the specific needs of our customers. We deliver high-quality anodized aluminum products that meet the highest standards of durability, aesthetics, and performance. Our aluminum anodizing process involves carefully preparing the surface of aluminum components and subjecting them to an...

When you choose INCERTEC, you're choosing a partner committed to excellence in every aspect of aluminum anodizing. Trust us to meet your specific requirements with a dedication to quality that goes beyond expectations. Reach out to us today for more information, and let us elevate your projects to new heights.

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Hard Anodizing Manufacturers

What is Hard Anodizing?

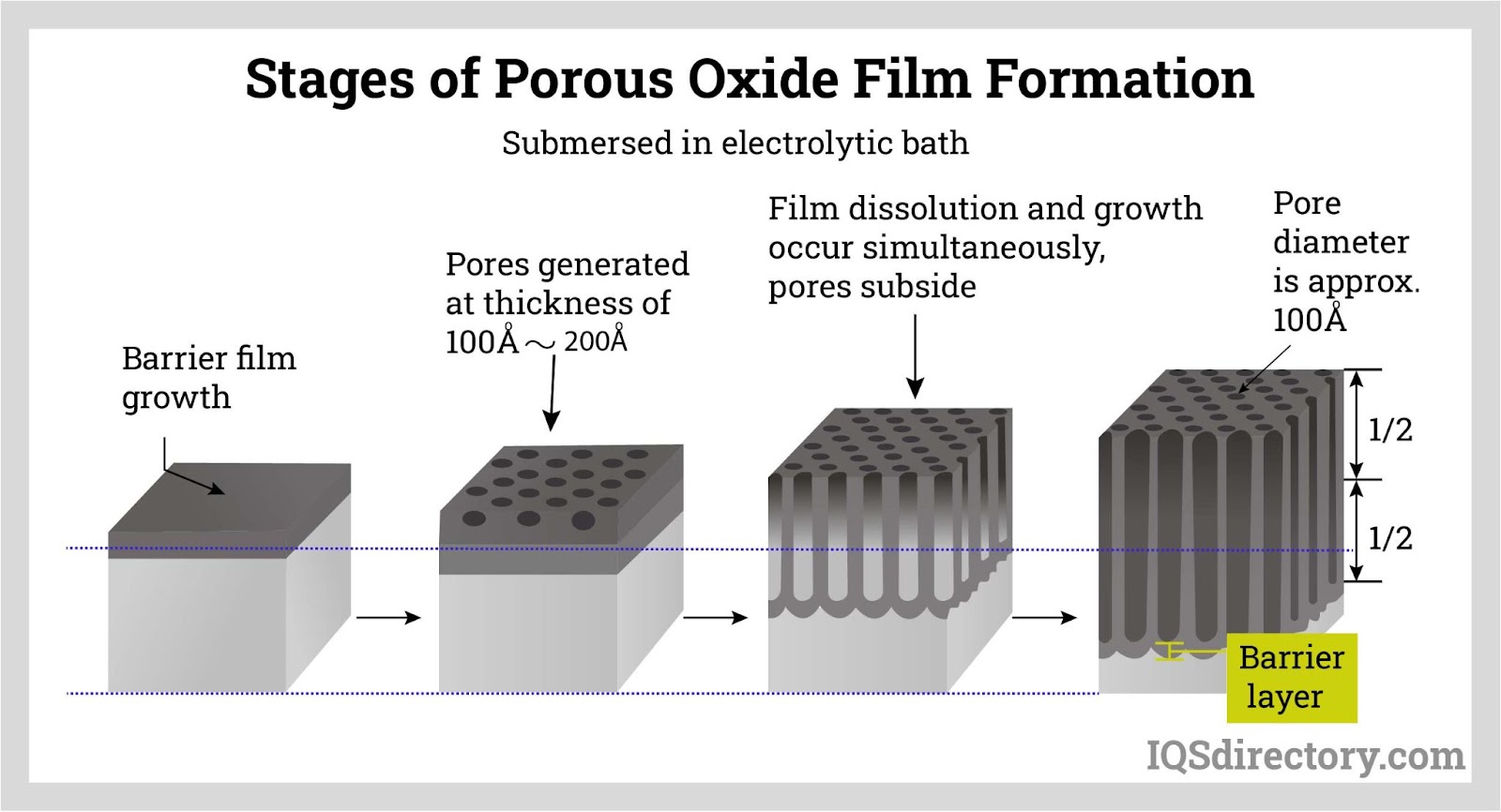

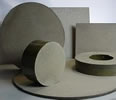

Hard anodizing (also known as hardcoat anodizing) is the process of applying a dense anodic coating of aluminum oxide by converting an aluminum alloy component that has been thoroughly cleaned and deoxidized into an oxide film using an appropriate electrolyte to make it thicker and more abrasion-resistant. The electrolyte usually used for this process is sulfuric acid that has been cooled nearly to absolute zero when voltages up to 100 volts are then applied with a current density of 24-36 amps per square foot.

What Distinguishes Hard Anodizing From Other Anodizing Processes?

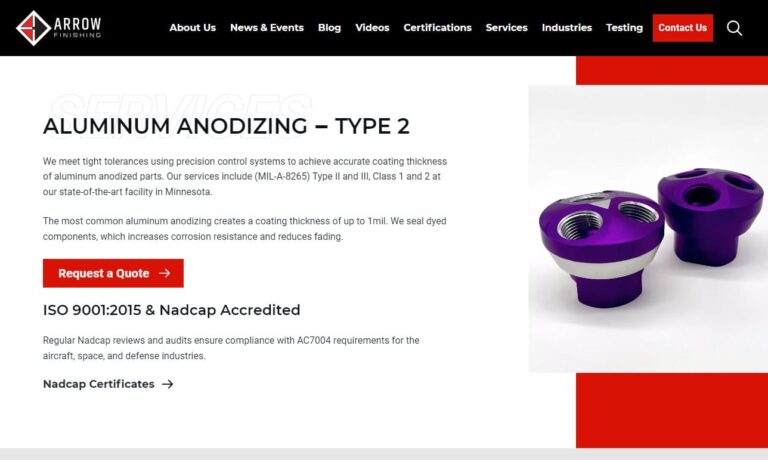

There are three forms of aluminum anodizing available and the terms are frequently, and incorrectly, used interchangeably. The first process is chromic acid anodizing, which produces an extremely thin (about 0.0001 inches thick) coating. The second process available is standard sulfuric acid anodizing, which produces a coating thickness (ranging between 0.0002 to 0.0006 inches thick) which can be decoratively dyed almost any color. A tougher, denser, thicker, and more abrasion-resistant coating is produced by the third process known as hard anodizing, which also uses sulfuric acid (at a higher concentration) and is carried out under more stringent processing conditions. Depending on the particular alloy being anodized, hard anodizing thicknesses surpass the other anodizing processes (thicknesses can range from 0.0005 to 0.0030 and beyond).

Distinguishing Features of Hard Anodized Aluminum

The hard-anodizing process of aluminum results in the following advantages:

- increased resistance to abrasion surfaces

- increased resistance to wear

- it creates a more durable finish than steel

- increased resistance to corrosion and other weather-related factors

- better aesthetics; it helps to restore tarnished aluminum; it may be readily be colored black (or other colors though they are less ornamental)

- it enhances dielectric characteristics (the coating serves as an electrical insulator) are enhanced; it is useful for electrical grounding enhanced lubrication is provided

- sterilization properties are promoted (useful for medical instrumentation)

Anodization Class Levels and Impact on Color

As a general rule, the thicker the coating added to aluminum, the better able it is to absorb more dye. Depending on the specific alloy and anodic thickness, Class 1 anodizing (or undyed) will only slightly alter the color of the aluminum. After being anodized at this level, the color of the aluminum depends on the alloy and coating thickness. While the majority of the 7xxx and 2xxx series will appear a more bronze-gray tone, the 6xxx series of aluminum will frequently take on a deep gray-black tint and aluminum alloys that have undergone anodizing at this level will appear gray or bronze. Black is by far the most popular color requested for dyed Class 2 anodizing coatings and will have a highly appealing, homogeneous appearance. Other colors don't appear as aesthetically pleasing and homogeneous after going through anodizing procedures at this level due to the dark tone of the undyed coating itself. Before manufacturing, sampling should be employed if a color other than black is required for items being anodized at this class.

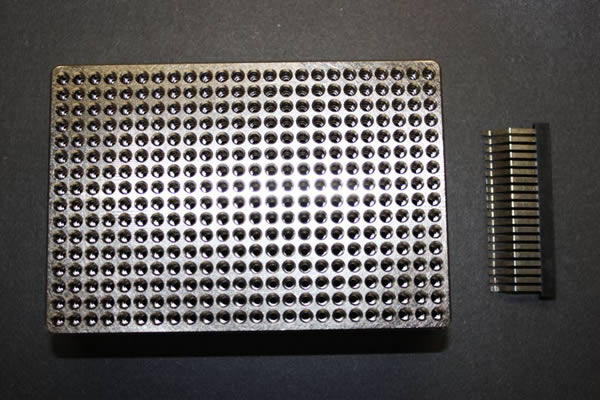

Impact of Hard Anodizing on Part Dimensions

Aluminum which has undergone anodization at Class 3 provides the potential for excellent coloring of this material due to the larger holes available within the metal available to absorb dyes. However, Class 3 anodization creates a coating thickness wherein half penetrates through the surface of the parts and the other half builds up on the surface. Therefore, there may be a 0.001" dimensional change per surface for a standard 0.002" thickness requirement. When precise tolerances are needed, it is very advisable to work closely with a customer to make sure that the end product's dimensions are determined by the coating's thickness.

You can Make Anodized-Free Zones in Hard-Anodized Aluminum?

All three levels of anodic coatings are electrical insulators, making it simple to mask surfaces so that they stay anodize-free when an electrical grounding surface is needed or when tight dimensional tolerances must be maintained. Simple rubber plugs, silicone stop-offs that are 3D printed, finely die-cut custom decals, and painted-on lacquer applied by hand or by a CNC-programmed robot can all be used for this.

Sealing of Hard Anodized Aluminum

Except for PTFE (polytetrafluoroethylene) sealing, the coating is typically left unsealed when hard anodizing is applied for wear or abrasion resistance, and this is the default in most specifications. On the other hand, hard anodizing needs to be sealed if the main objective is corrosion resistance or a combination of corrosion and wear resistance. To ensure that the dye won't fade or bleach away, any dyed hard anodizing must generally be sealed. Deionized water, sodium dichromate, nickel acetate, PTFE, or a combination of two or more of these materials can all be used for sealing.

Applications for Hard Anodizing

There are countless applications for hard-anodized aluminum. Here, consider its usefulness for just a few parts created from this material:

- Valves

- Pistons

- Sliding parts

- Hinge mechanisms

- Cams

- Gears

- Swivel joints

- Insulation plates

- Blast shields

Sectors That Gain From Hard Anodizing

Whether it's the enhanced sterilization or lubrication provided, its dielectric properties, or from some other benefit provided, the list of businesses utilizing hard-anodized aluminum is nearly endless. Below is a partial list of industrial sectors benefiting from this incredible material:

- Aerospace

- Automation / robotics

- Automotive

- Electrical

- Food manufacturing equipment

- General manufacturing

- Hydraulics / pneumatics

- Machine tools

- Medical

- Military / defense

- Optical devices

- Sporting goods

Choosing the Proper Hard Anodizing Supplier

To make sure you have the most constructive outcome when purchasing Hard Anodizing from a Hard Anodizing Company, it is important to compare at least 4 Companies using our Hard Anodizing directory. Each Hard Anodizing Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Hard Anodizing company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Hard Anodizing businesses with the same quote.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services