Valmont Coatings

Valmont Coatings Request A Quote

Los Angeles, CAValmont Coatings is a leading provider of coating solutions to a wide range of industries. With over 50 years of experience in the industry, Valmont Coatings has built a reputation for providing high-quality coating solutions that are designed to meet the needs of their customers. Their services include an extensive range of metal finishing services, including Aluminum Anodizing. Aluminum Anodizing is a process that is used to create a protective layer on the surface of aluminum. This layer is created by an electrochemical process that converts the surface of the aluminum into an oxide layer, which is then sealed to create a protective barrier. This process improves the corrosion resistance of aluminum, as well as its wear resistance, and can be used to create a variety of colors on the surface of the material. Valmont Coatings offers a range of Aluminum Anodizing products and services that are designed to meet the needs of their customers. Their services include both Type I and Type II anodizing, which allows them to create a wide range of finishes on aluminum. Type I anodizing is a chromic acid anodizing process that is used to create a thin protective layer on the surface of the material. This process is used primarily for decorative applications, as it creates a clear or slightly yellowish finish on the surface of the aluminum. Type II anodizing, on the other hand, is a sulfuric acid anodizing process that is used to create a thicker and more durable layer on the surface of the aluminum. This process can be used to create a variety of colors on the surface of the aluminum, and can be used for both decorative and functional applications. Valmont Coatings also offers a range of sealing options for their Aluminum Anodizing services. These sealing options include hot water sealing, nickel acetate sealing, and sodium dichromate sealing. Each of these sealing options provides a unique set of benefits, and Valmont Coatings can help customers determine which option is best suited to their specific needs. In addition to their Aluminum Anodizing services, Valmont Coatings also offers a range of other metal finishing services, including electroplating, powder coating, and liquid painting. They have a team of experienced professionals who are dedicated to providing their customers with the highest level of service and support, and they are committed to delivering high-quality products that meet or exceed their customers' expectations. Overall, Valmont Coatings is a trusted provider of high-quality Aluminum Anodizing services and other metal finishing solutions. Their commitment to quality, customer service, and innovation has made them a leader in the industry, and they continue to be a preferred choice for customers across a wide range of industries.

Aluminum Anodizing

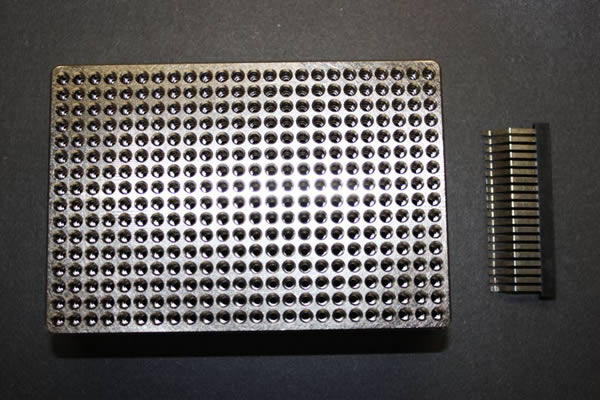

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services